EXTREME TORQUE CAPACITY. MAXIMUM DRIVEABILITY.

A competition DCT pioneer, DEKA transmission upgrades combine the highest holding power available with smooth, OEM ride feel and comfort.

Browse by Make

BMW ZF 8HP76 with DEKA Stage 3 Upgrade

Driver: Bernard M, @s58nyc

Application: BMW G82 M4

Power: 1,000+ WHP | 995+ N·m

The DEKA Difference

-

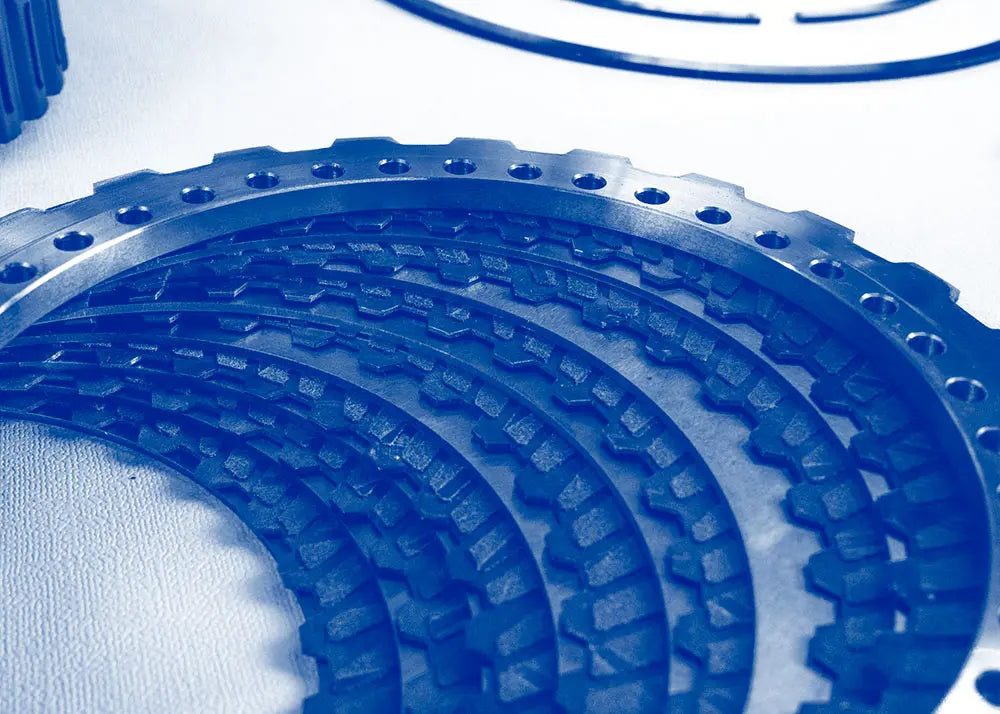

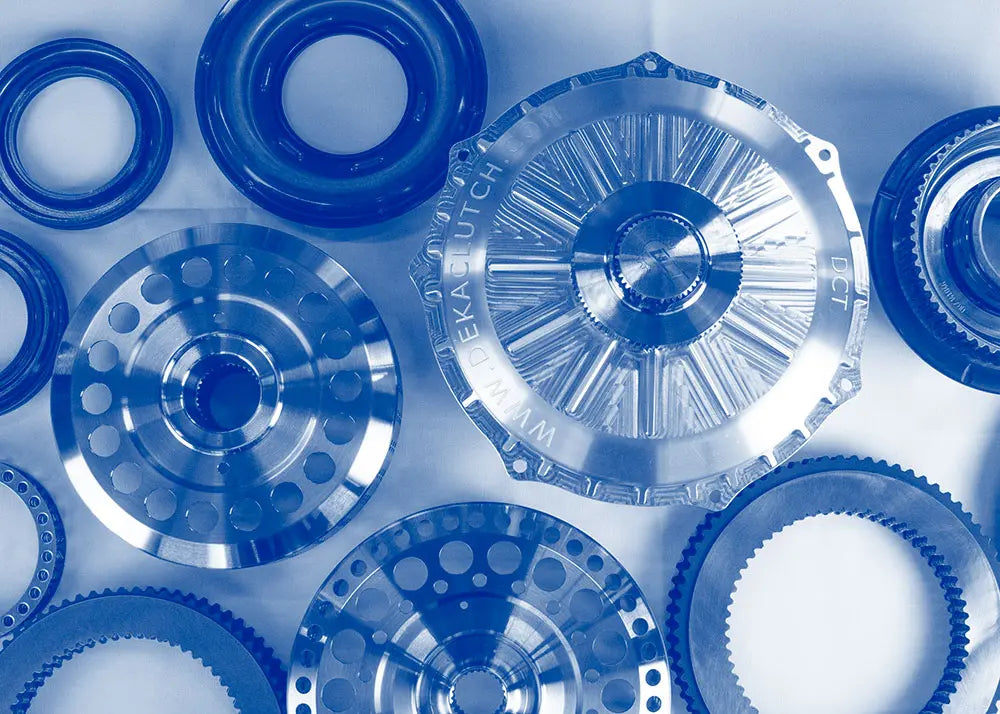

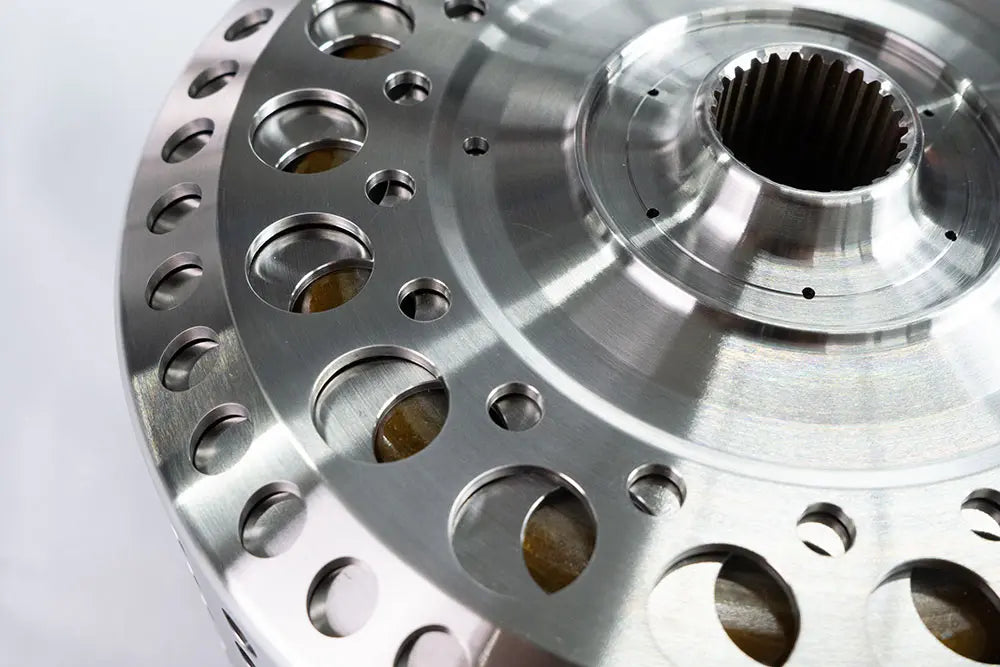

Materials

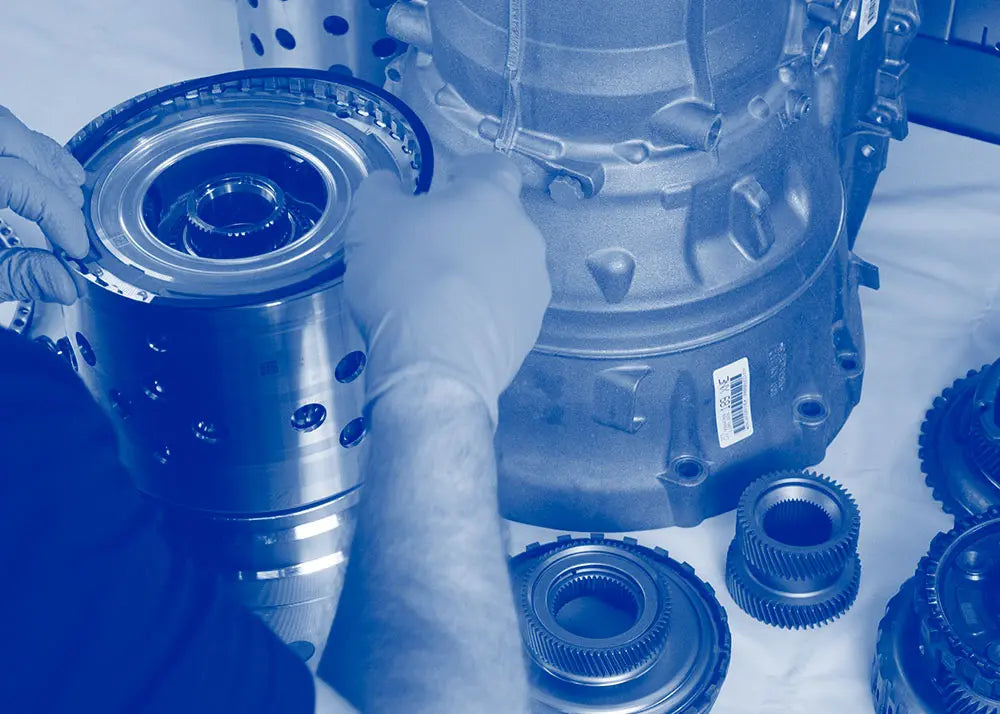

Featuring billet hubs, patented frictions and heat treated steels, fresh rings, seals, and gaskets, DEKA transmission quality and performance are unmatched.

-

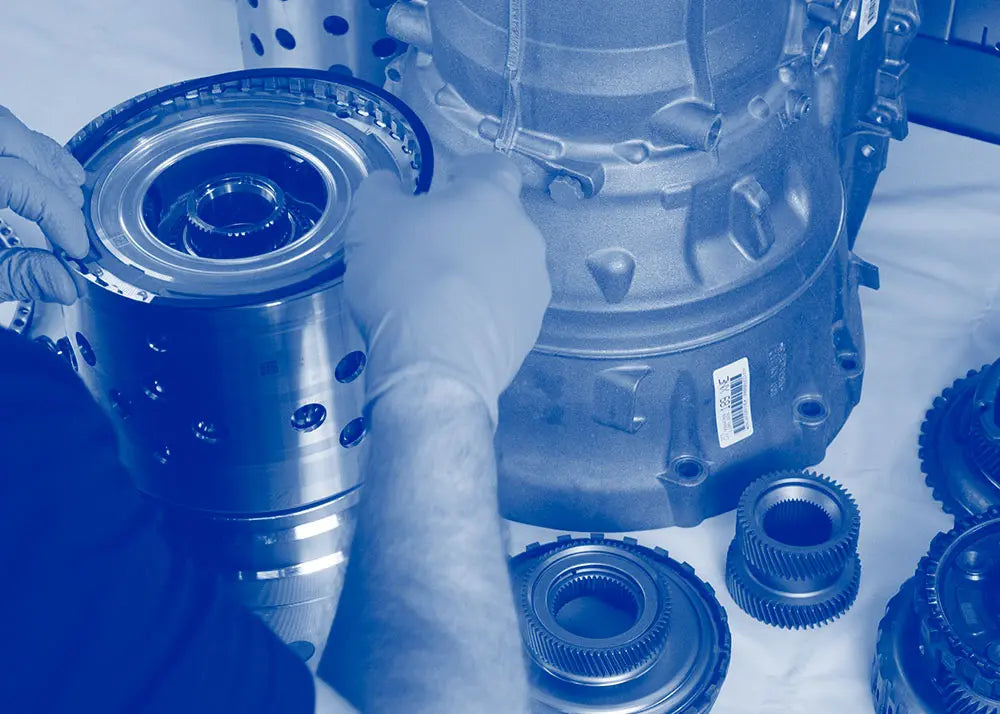

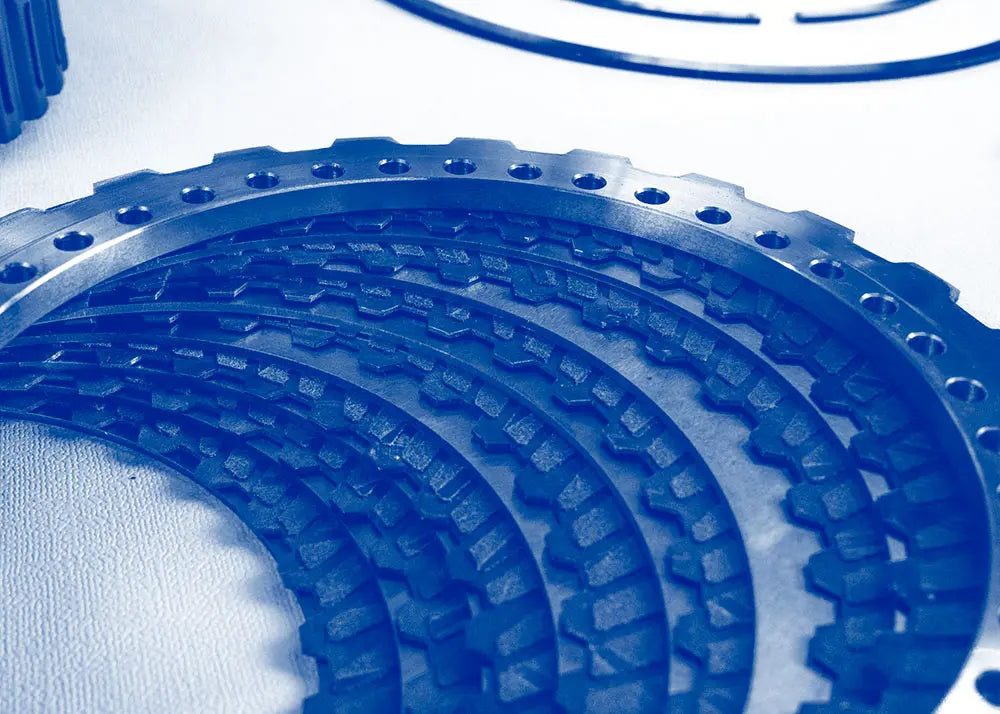

Construction

Every DEKA transmission build is the result of careful engineering, analysis, and upgrade, preparing your drivetrain for high performance applications.

-

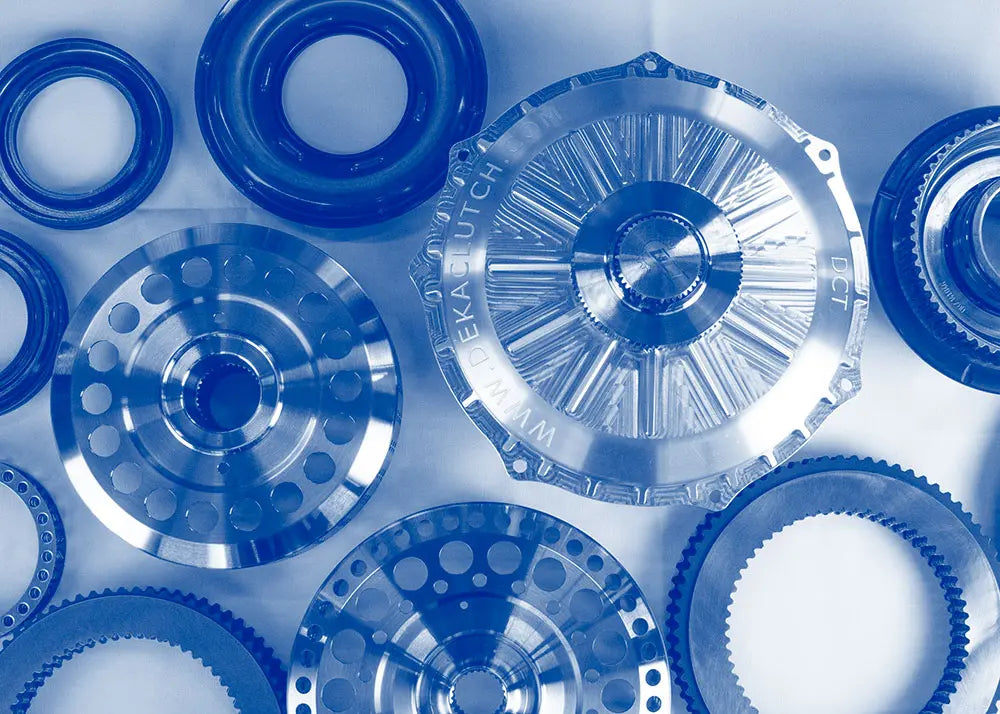

Assembly

Using a no compromise approach, each DEKA performance transmission is hand-assembled by expert craftsmen in their Miami, Florida headquarters.

Audi DL800 with DEKA HD2000 Upgrade

Driver: Jimmy C, @jimmysupragtr

Application: Audi R8 V10

Power: 1,500+ WHP

-

Audi DQ500 0BT DCT Upgrade

Regular price From $1,899.99 USDRegular priceUnit price / per -

VW / Audi DQ250 DSG Upgrade

Regular price From $1,949.99 USDRegular priceUnit price / per -

Audi / Lamborghini DL800 DCT Upgrade

Regular price From $3,199.99 USDRegular priceUnit price / per -

Audi DQ500 Flywheel Hub

Regular price $699.99 USDRegular priceUnit price / per

BMW ZF 8HP76 with DEKA Stage 3 Upgrade

Driver: Vlad F, @fairbird_sdrperformance

Application: BMW G80 M3

Power: 1,000+ WHP